IDEA-4S provides the constructors and designers of machines with the ideal technology for digitizing the drive technology and motor spindles in machine tools. This enables process analysis, performance improvements during production and new digital services.

Mr. Markus Weber, Head of Development Spindle Technology, explains in the video the beneficial features and application possibilities of our embedded system IDEA-4S.

The benefits of IDEA-4S for drive technology can already be seen in the design of spindles and motors. The reason is that the embedded system can be easily installed in different drive components. Though initially developed for GMN spindles, it can now be used for all commercially available motors.

During operation, the compact, easy-to-integrate information technology enables every spindle and motor to collect relevant information, enrich it and interpret it.

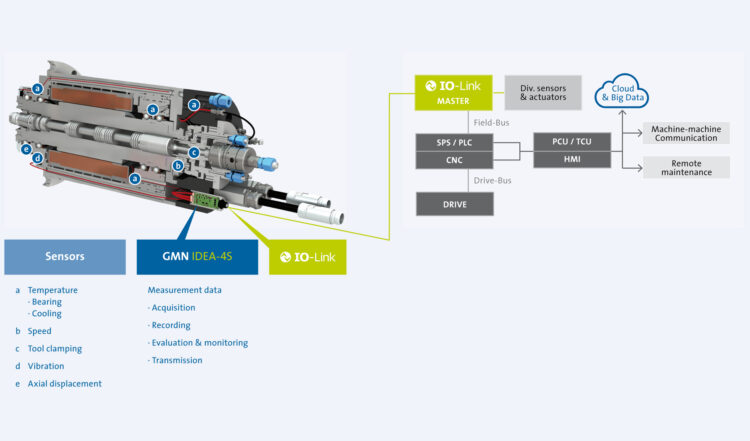

The IDEA-4S electronics determine the data and makes it available for exchange and communication in production networks using bidirectional signals via a digital IO-Link interface.

IO-Link is the first standardised IO technology (IO = Input / Output) worldwide (IEC 61131-9) for the communication with sensors and also actuators.

IDEA-4S opens up new horizons in drive technology for machine tools.

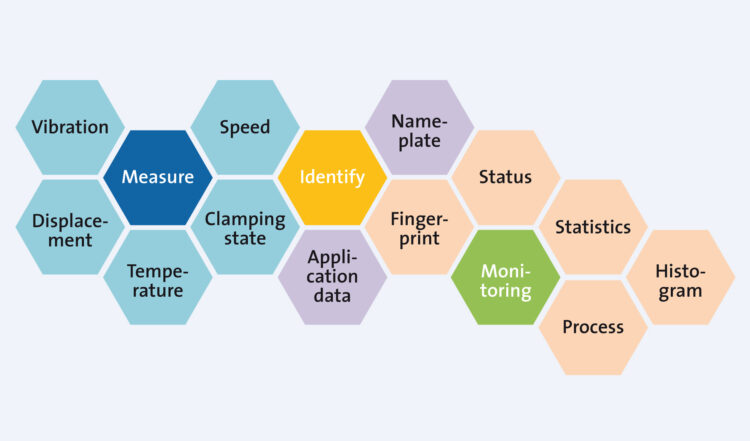

The system continuously records a series of cyclic sensor signals, evaluates them simultaneously and transmits the process values with information on the:

Additional acyclic information, such as the digital rating plate and asset management information on the drive components, can be retrieved and written manually. Users can also receive statistical values for their operating data.

The IDEA-4S electronics, for the intelligent acquisition and analysis of data for spindles, features up to five analog connections for temperature sensors (PT100), one analog connection for a speed sensor in accordance with NAMUR (= an international user association of automation technology and digitalization in process industries), and three digital interfaces for sensor systems (for example, an MSU unclamping unit from OTT-JAKOB.) The electronics also contain a three-axis vibration sensor within.

The signals from the sensors or sensor systems connected to the electronics in the spindle and the vibration signals are recorded, evaluated and made available via an IO-Link interface.

The IDEA-4S posseses a digital nameplate to identify the spindle. It can store application data such as machine numbers or installation dates.

For each sensor, IDEA-4S provides statistical values like minimum and maximum values or status (such as alarms and faults), along with histograms to track the operating time in specific value ranges. Moreover, the system can analyze a spindle’s fingerprint or monitor a process.

The IDEA-4S electronics is an IO-Link interface for spindle monitoring that transmits sensor values as process data and other acyclic information such as diagnostic data or configuration parameters. The device needs an IO-Link master to operate.

An IODD file (IODD = IO-Link device description) is required to configure the electronics. The IO-Link interface is fully described in the IODD. GMN can supply the IODD upon request.

IDEA-4S uses COM3 speed (COM3 = 230,4 kbit/s) as per the latest IO-Link Specification 1.1.3. Implementing IDEA-4S in a modern IIoT infrastructure can be achieved using the IO-Link interface.

The embedded IDEA-4S system fits perfectly into modern IIoT structures. IO-Link can be used as an interface independently of fieldbus systems and, therefore, employed universally for all kinds of control systems.

Modern IO-Link masters permit a seamless connection to IIoT infrastructures without affecting the control system’s performance. IO-Link also allows simple point-to-point communication.

This means that devices can be easily replaced without tools and implemented easily thanks to the complete device description.

Another argument favoring IO-Link as an interface is its high acceptance level. The number of IO Link nodes rose to more than 21 million in 2020, and the community keeps growing.

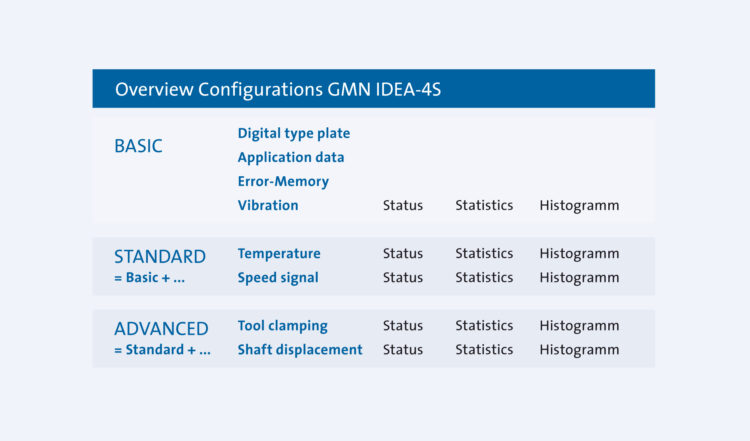

The system can be configured according to the sensor interfaces used.

There are three different product lines: Basic, Standard and Advanced: