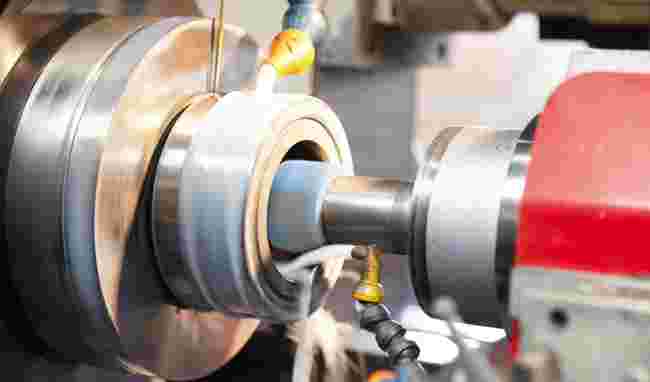

Whether grinding especially small holes or those of a larger diameter: GMN grinding spindles provide outstanding grinding results thanks to high load capacity, stiffness, smoothness and precision.

Especially very small holes and therefore grinding quills with small diameters pose the highest requirements for maximum speed and stiffness.

GMN offers for all internal grinding machining a uniquely broad range

of high-frequency grinding spindles.

These are for manual tool change e.g. UHS, HS, HV-X and HSX series,

for automatic tool change e.g. HC and HCS series, as well as

for other drives e.g. TSA, TSI and TSP series.

In addition, helpful options (such as coolant supplied through the spindle shaft) and various sensors (such as speed sensors, vibration monitoring, A/E sensors) are offered.

GMN grinding spindles for external grinding

e.g. TSAV and TSEV series

are characterized by their high load capacity.

They are available for external drives (such as using belts) or with installed or integrated motors e.g. HGS, HGC and HGT series.

Whenever high precision is required,

TSE, TSEV and HGS series spindles for manual tool change or

HGC and HGT series spindles for automatic tool change

are available as grinding spindles.

Optionally, they are delivered with an automatic balance system and/or A/E sensors (sunk recognition).

Due to the special designs,

the HV-X, HSX, HV-P and HSP series grinding spindles

are extraordinarily suited to grinding flat surfaces on small and middle-sized inner holes.

High stiffness, precision and extraordinary smoothness are needed in this application in order to achieve the desired machining results.

GMN has suitable customer-specific motor spindles for this

such as WS and WSE series.