The electronically controlled lubrication unit PRELUB is optimally adapted to the oil-air lubricated GMN spindles and guarantees a long service life.

The precisely controllable lubricant dosing ensures effective bearing lubrication as well as maximum operating security during the start and shut-down phases.

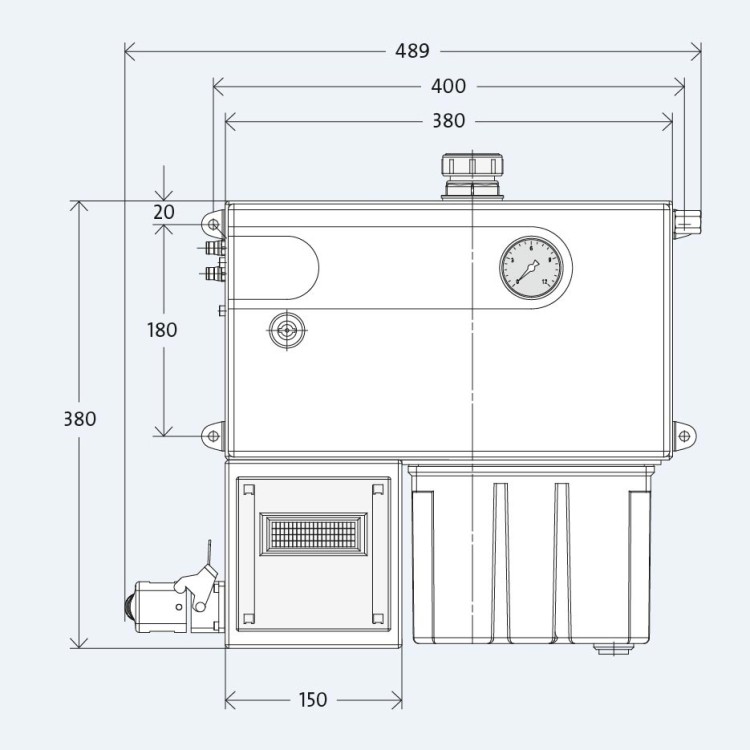

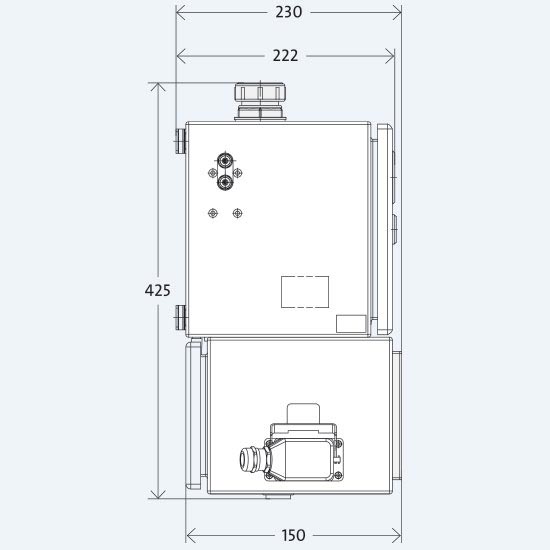

With a maximum of 4 connections, the lubrication unit offers concomitant, individual provision to a maximum of two spindles, and takes up very little room.

The connection opportunities to commercial personal computers provides an overview of operation with a multi-language menu structure.

Accessories required for assembly, e.g. lubricant hoses, hydraulic and air hoses, control manometer and filtered lubricants are available from GMN.

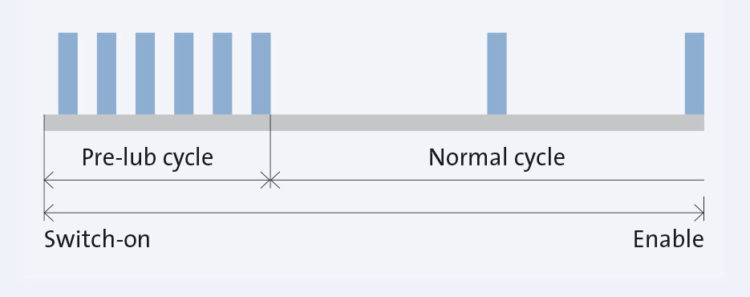

1. Start pre-lubrication (release signal not used for spindle operation)

2. Several lubrication pulses within a short time, depending on the line length between the spindle and the mixing distributor (pre-lubrication cycle)

3. Release signal after the pre-lubrication time is completed

4. Transfer to the normal cycle (cycle time) as per the GMN operating manual

The duration of pre-lubrication depends upon the length of the connected

lubrication lines.

(Details: see operating manual)

In order to ensure the long-term effective lubrication function of the unit, it is necessary to filter the oil and air supply.

The provided cartridges for one maintenance-related filter exchange can be obtained from GMN.

The use of filtered oils with friction and wear-reducing additives ensure the long-term reliable operation of the spindle at maximum speeds.

Detailed specifications for the required lubricant as well as determination of cycle times and lubricant pressures are contained in the operating manual contained in the delivery.

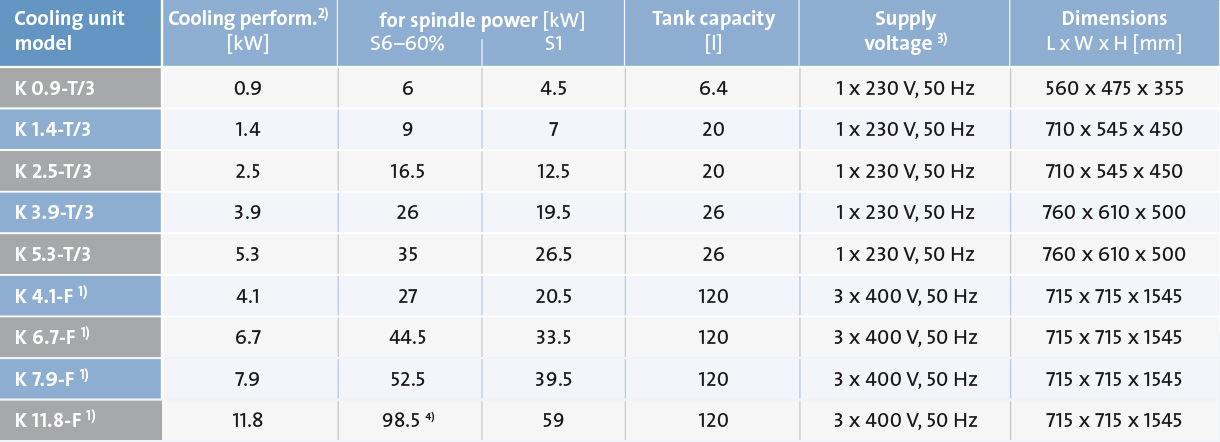

The reliable availability of the required coolant quantity and temperature reduces the heat generation caused by the operation and ensures maximum detachable spindle speeds.

GMN cooling units ensure precisely adjustable temperature and quantity delivery of the cooling medium and achieve consistently low operating temperatures.

High-precision control accuracy reduces axial shaft misalignment, caused by temperature fluctuations in the coolant.

1) In addition to high-pressure monitoring, also available with low-pressure monitoring in the coolant circuit.

2) At 37 °C ambient temperature and 20 °C water temperature. The performance is reduced at higher ambient temperatures.

3) Other voltages and frequencies upon request.

4) Assumptions: Spindle power ≥ 80 kW means reduced coolant performance needs of 12% or 10%, related to spindle power.