The corrosion-free material properties mean that the plastic seals from GMN are particularly well-suited for protecting from watery liquids.

Polyoxymethylene has a high resistance to a variety of acids (lactic acids), chemicals and fungi. GMN non-contact plastic seals are approved for the food industry.

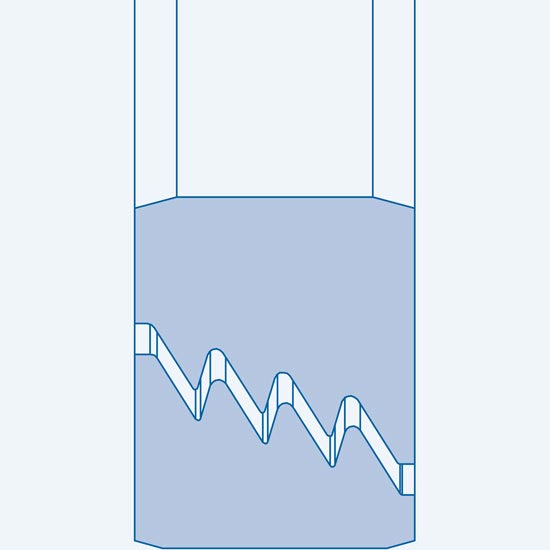

The S design is particularly suited for use with normal spray load for rotating shafts and hubs.

Greased seals: All types in the S design are also available with a greased sealing gap for improved protection from dust. (Ordering designation: SdxDxB greased)

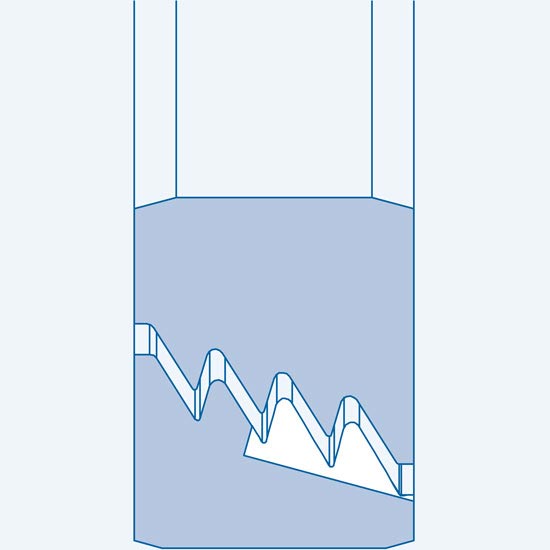

The SA design is additionally equipped with a drainage groove on the outer ring for rotating shafts that removes any penetrated liquid during heavy and direct spray impact.

The technical data for the SA design is the same as for the S design.

Thanks to their non-contact design, GMN labyrinth seals guarantee completely frictionless operation.

GMN seal components work completely wear-free and offer an unlimited service life.

The non-contact design of GMN seal components guarantees operation free from abrasion that fulfills the highest cleanliness requirements. (Approved for the food industry.)

The small distance between the outer and inner ring guarantees highly effective sealing and very good protection from fouling.

Because no friction heat is generated, neither the seal nor the adjacent components or the lubricant are subjected to thermal loads.

The frictionless design enables operation without performance losses. This means that the seal offers maximum sealing effect with reduced energy consumption even at high speeds.

GMN labyrinth seals achieve 2–4-layered labyrinths in the smallest space.

GMN labyrinth seals in S and SA design use centrifugal force to improve the sealing effect. Penetrated media is transported to the large gap diameter through rotation. Therefore, the seal must always be mounted so that the large gap diameter is on the impact side.

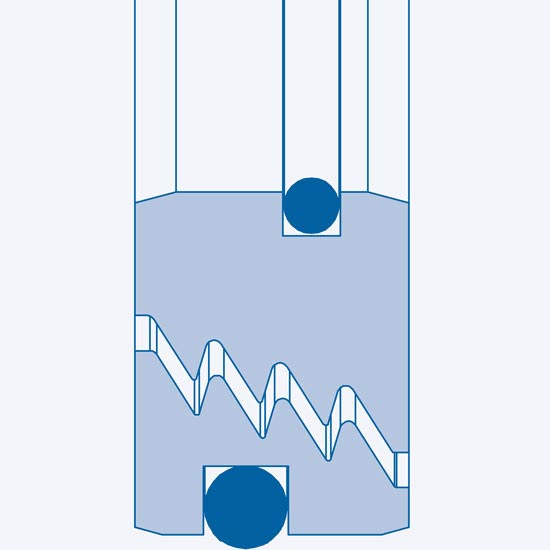

A drainage groove on the inner ring is available for applications with a rotating hub (special solution SI).

For greased seals, the entire sealing gap is filled with grease for optimal protection against ultra-fine particles.

GMN offers special solutions optimized for the specific requirements above and beyond the extensive standard product range for non-contact plastic seals. Customer-specific dimensions can be produced on request.

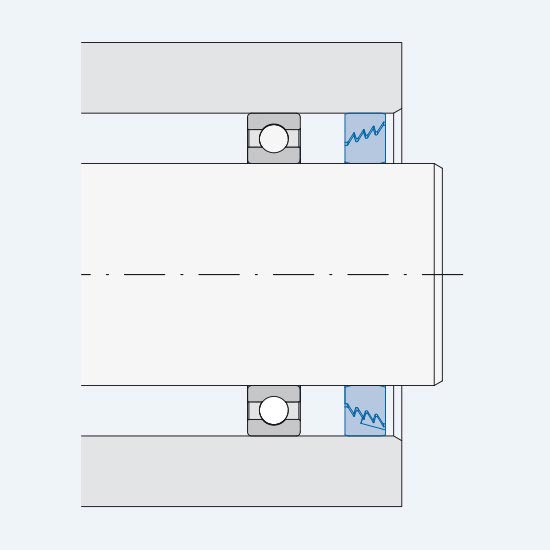

To secure the press fit, in particular of the outer ring in temperatures up to 80 °C, an O-ring is mounted in a groove on the seal outer ring (optionally also on the inner ring).

The design with O-ring is available in all GMN sizes. (Quotations on request)

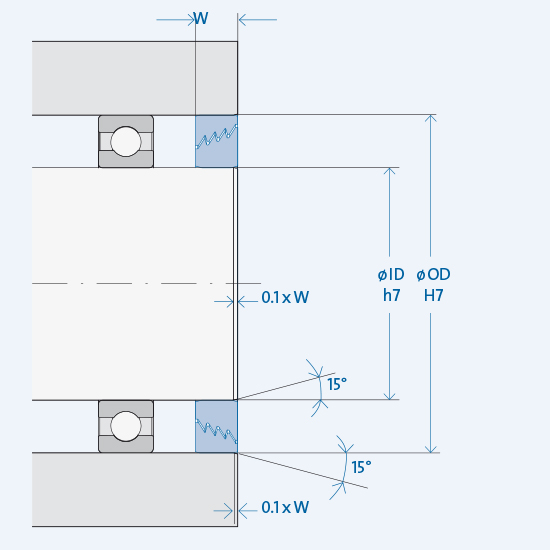

Tolerances

Housing: H7

Shaft: h7

Surface quality: Rz ≤ 16 µm; Ra ≤ 3.2 µm

Installation

The length “l” of the chamfering of shaft and housing depends on the width “W”.

l = 0.1 x W

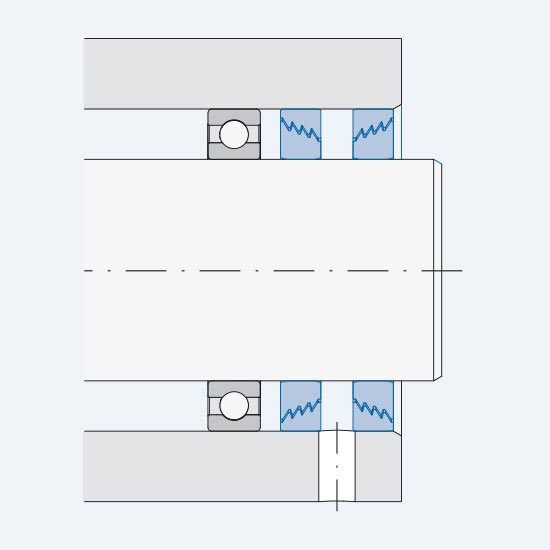

With tandem arrangement, the plastic seals are mounted with different orientation. One seal offers protection against potential fouling from the outside, while the other seal seals the lubricant on the bearing. The smaller gap diameters are oriented to the interspace of the seal (min. distance 5 mm).

When installing the “SA” design, the return groove is located at the lowest point on the stationary ring.