Highly sensitive optical or magnetic systems are protected effectively from contamination. The frictionless operation of GMN sealing solutions enables force-free positioning of encoders and guarantees optimal measurement results.

The quality and precision of dynamically sensitive systems like encoders depend, among other things, on the disturbance variables of the components used. For example, the unavoidable friction of a contact seal is a disturbance variable of this kind.

Non-contact seals work completely friction-free and therefore offer clear advantages in applications like these.

The efficiency of electric motors is a key performance characteristic in international competition. Non-contact seals work completely friction-free and therefore cause no performance losses in contrast to conventional systems.

Seals from GMN therefore make an important contribution to increasing the effective performance and optimizing the environmental footprint.

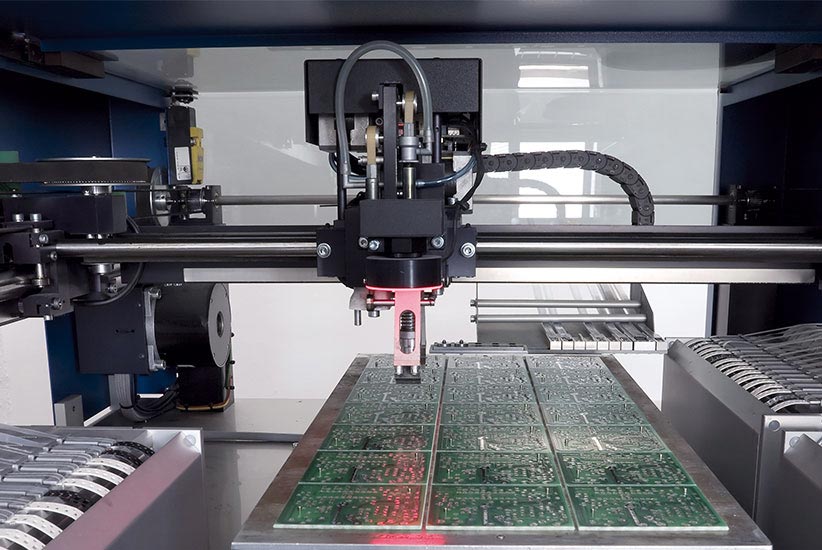

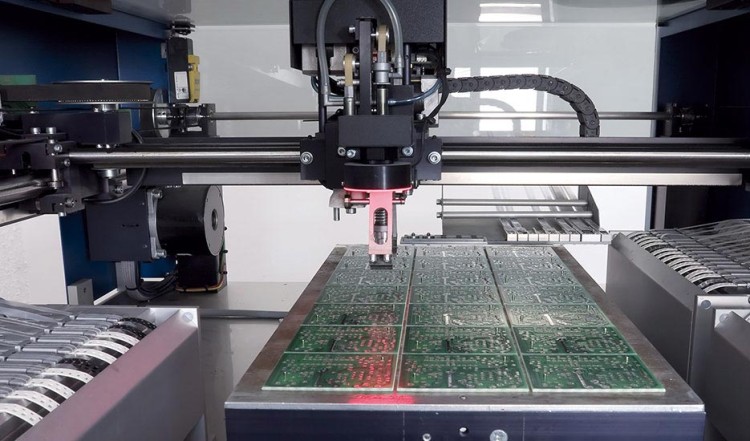

SMD automatic placement machines place the electronic components on the circuit boards at extremely high speeds and with a high level of precision. Stepper motors and high-precision encoders are used for exact positioning.

Non-contact seal on the drives of these installation systems protects the bearings and the sensitive optical components (e.g. incremental disks) from fouling and enables smooth operation without any disturbing influence on the sealing components.