The right handling of ball bearings related to storage, installation-preparation and grease distribution processes ensures unlimited use, optimal performance characteristics and long life expectancy.

Proper storage of GMN products ensures bearing-specific performance characteristics until they are installed.

Shelf life of preserved and grease lubricated ball bearings: max. 2 years (with proper storage)

Further information about storage is available on request.

Careful preparation of the installation environment and relevant

components assure unrestricted utilization of GMN ball bearing

performance characteristics.

Information on the mounting and installation of GMN spindle bearings and ball bearings.

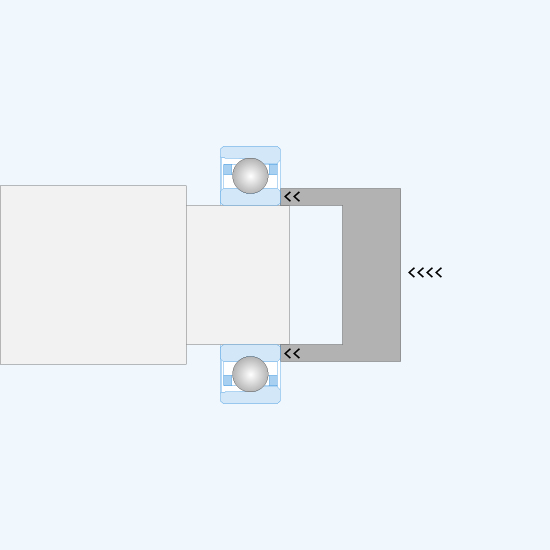

In this case, the ball bearing is correctly pressed onto the shaft with a fixed position. The installation forces are only introduced through the inner ring. The balls and grooves remain force-free and undamaged.

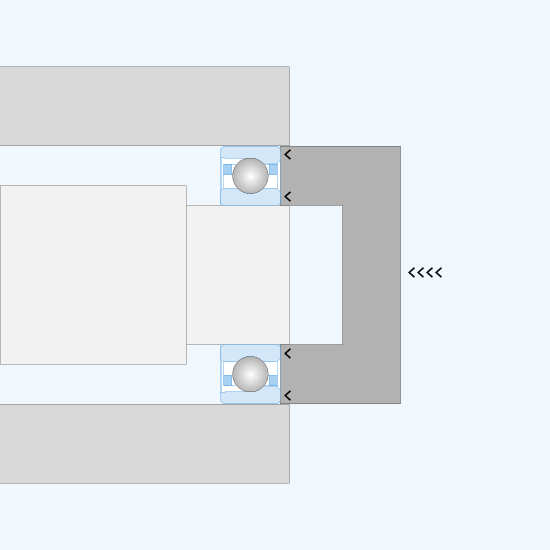

In the case that two fixed seats are provided, the bearing can be pressed evenly over both rings, and thus installed.

This ensures that the balls and grooves are undamaged.

In the case of oil-lubricated bearings, no particular break-in process is generally prescribed, but it has proved to be advantageous if

You can find technical information about oil lubrication in our downloads.

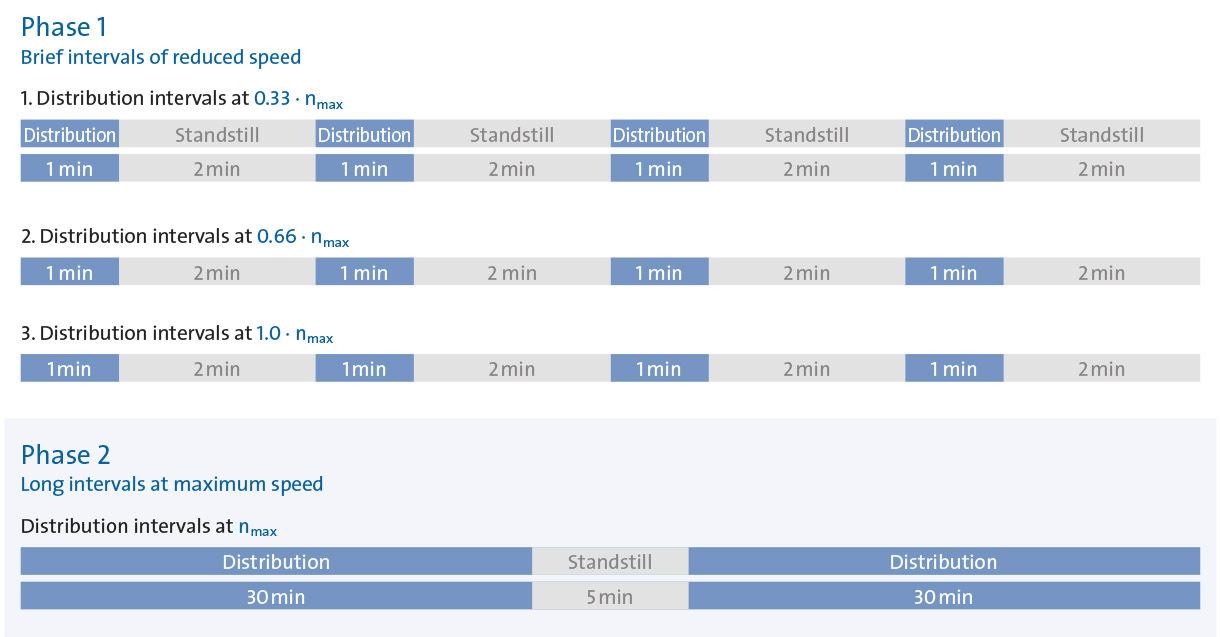

The required grease distribution process ensures even bearing lubrication, and optimizes distribution of the lubricating grease in the bearing (grease thickener is removed from the ball rolling area, and the basic oil evenly wets the greased areas).

You can find technical information on grease lubrication in our downloads.

You will find technical information on grease distribution in our downloads.