In addition to our special bearings, GMN develops and manufactures ready-to-install, complex bearing systems. By assigning your entire bearing project to GMN you can fully focus on your core competencies.

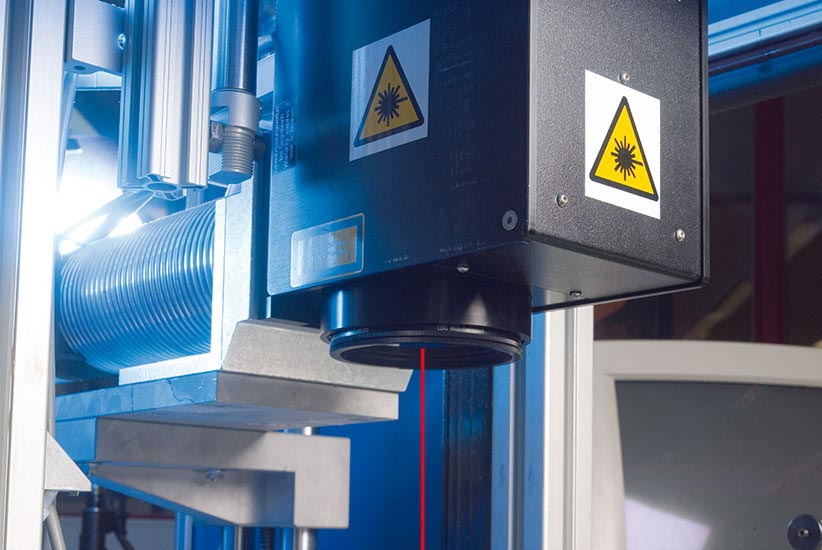

Where individual bearings are no longer a solution, bearing systems can be the key to your success. It does not make any difference whether your application is equipped with high-precision optics or runs under extreme ambient conditions. Bearing systems give your product a unique selling proposition and by using a modular approach can grow into economic variant diversity Individual requirements for lubrication, used materials, needed sizes and required precision are considered.

Often the success of a product relies on the interplay of many details, which are far more than the design of a ball bearing. In the end, they all must fit perfectly. In this way, corrugated seats, housing fittings and internal positioning forces are optimized for the respective application situation, and the lubricant used can not show any negative side effects in conjunction with the given work environment. We offer: